MIRCROBIAL CONTAMINATION IN TURBINE OIL SYSTEMS? ARE YOU KIDDING!?

Microbes do not care whether operators accept the science.

Can microbes degrade turbine oil and cause damage to turbine oil systems?

The short answer is yes.

In 2018, as part of an Energy Institute sponsored project, I invited more than 100 turbine system operators to complete a survey designed to assess biodeterioration risk awareness and operational measures (for example, condition monitoring practices) for reducing the risk. Concurrently, I sent a similar invitation to power generation facility operators responsible for emergency standby diesel generator fuel systems. In contrast to the 23 % response from the folks responsible for fuel systems, I received no complete responses from folks responsible for turbine oil systems. Clearly, personnel responsible for fuel systems were more aware of the risk of biodeterioration than were their colleagues responsible for turbine oil systems.

Turbine oil and turbine oil system biodeterioration is not a common occurrence, but it does happen. A major challenge is that the people who need to connect the dots, are typically unaware of the potential for microbes to grow in these systems.

In this What’s New article I will summarize thet types of damage microbes can cause to turbine oil systems when sufficient water is present.

Water

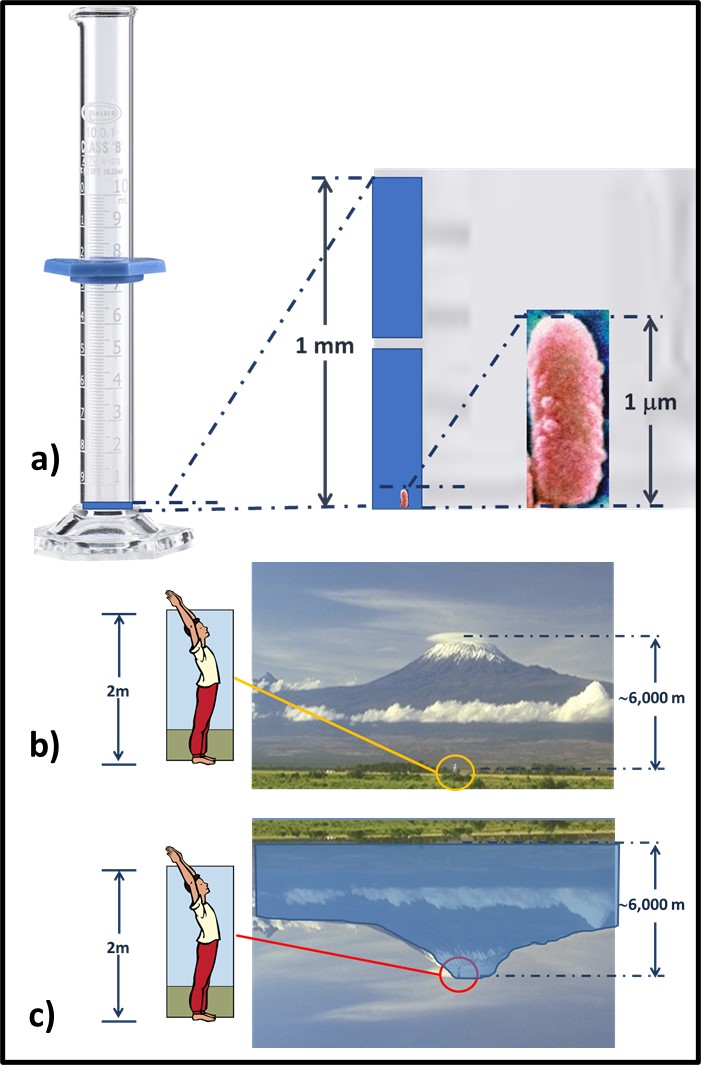

Although microbes require free water (water that has coalesced into droplets or a continuous phase) the volume they require can be vanishingly small. In my education courses, I compare a 1 µm (0.000039 in) bacterium on a surface under a 1 mm (0.039 in) film of water (Figure 1a) to a 2 m (6ft) tall person standing on the floor of a lake that is as deep as Mt. Kilimanjaro is tall (6,000m – 20,000 ft – Figures 1b and 1c). Moreover, a one mL (0.034 oz) drop of water can be a habitat for more than a billion bacterial cells. Thus, undetectably small traces of water can support substantial microbial communities and those communities can degrade the oil and damage the turbine oil system. Note: this phenomenon applies equally traces of water found in fuel and hydraulic fluid systems.

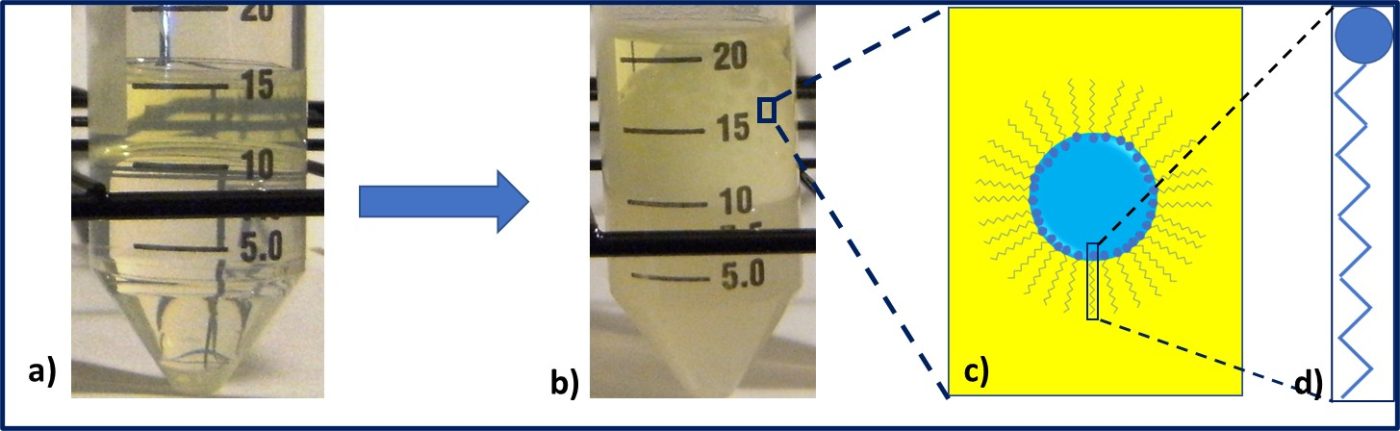

Fig 1. Relativity – the environment provided by a 1 mm thick film of water – a) relative dimensions of a 1 µm -long bacterium in 1 mm of water in graduated cylinder; b) a 2 m tall person standing at the base of Mt. Kilimanjaro; c) the same person standing on the floor of a lake that is as deep as Mt. Kilimanjaro is tall.

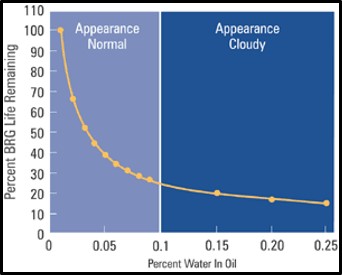

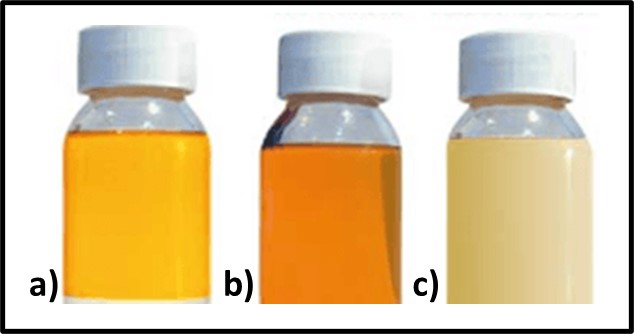

The most common symptom of uncontrolled microbial contamination in turbine oils is increased entrained water as determined by the Karl Fischer test (ASTM Test Methods D1533 or D6304). Water’s solubility in turbine oils can range from 20 µg kg-1 (i.e., ppt) to 60 µg kg-1. Optimally, it is maintained at <50 µg kg-1. Figure 2, copied from an article in Machinery Lubrication, shows that petroleum based turbine oils typically become visibly hazy once the water concentration reaches approximately 100 µg kg-1 (0.1 %). The water solubility in phosphate ester (PE) based oils is approximately 10x greater (i.e., 1,000 µg g-1). Haze (cloudiness) indicates that the concentration of water in the oil has exceeded its solubility and that the water has coalesced into micelles (droplets). Figure 3a shows oil in which the water concentration is below the saturation concentration. Figures 3b and 3c show how increased volumes of dispersed water increase the oil’s haziness; ultimately forming an invert emulsion.

Fig 2. Relationship between water concentration and haze (and bearing life).

Source: Water In Oil Contamination (machinerylubrication.com)

Fig 3. Relationship between water concentration and haze – a) water concentration is below the saturation level – the oil is clear and bright; b) water concentration is greater than saturation level – the oil has become hazy; c) sufficient water is present to form an invert emulsion.

What does this have to do with microbes? Microbes can produce detergent-like molecules called biosurfactants. As illustrated in Figure 4, biosurfactant molecules create stable, invert (water-in-oil) emulsions. Invert emulsion micelles provide oil-water surface area that facilitates microbes’ ability to use base-stock and additives as food.

Fig 4. Biosurfactant-based, invert emulsion – a) oil over water that is infected with biosurfactant—producing microbes; b) sample show in (a), 30 min after vigorous shaking – note formation of a stable, invert-emulsion; c) invert emulsion – water droplet encased by biosurfactant molecules; d) biosurfactant molecule showing polar (charged) head and non-polar (chargeless, hydrocarbon) tail.

Thus, water provides an environment in microbes can thrive. Thriving microbes produce biosurfactants that degrade the oils water separability properties (ASTM Test Method D1401) and thereby make nutrients from oil more readily available to the infecting microbes. Now I’ll summarize the primary consequences of providing microbes with the water they need to thrive.

What damage can microbes cause to turbine oils?

The process by which microbes (and all other living things) consume nutrients and convert them into food, energy, and waster is called metabolism. Microbes can directly consume oil additives, including corrosion inhibitors, antioxidants, and lubricity additives. They can also consume base oils. The net effect of this metabolic activity includes:

- Decreased base number

- Decreased oxidative stability

- Decreased water separability (as noted above)

- Decreased corrosion inhibition

- Increased acid number

- Increased particle load

- Increased water content (as noted above)

- Degraded viscosity and viscosity index properties

You’ll probably notice that each of these symptoms of turbine oil degradation can also be caused by non-microbiological (abiotic) processes. That creates a significant challenge when attempting to distinguish between biodeterioration and abiotic deterioration. More on that below.

What damage can microbes cause to turbine oil systems?

Premature filter plugging

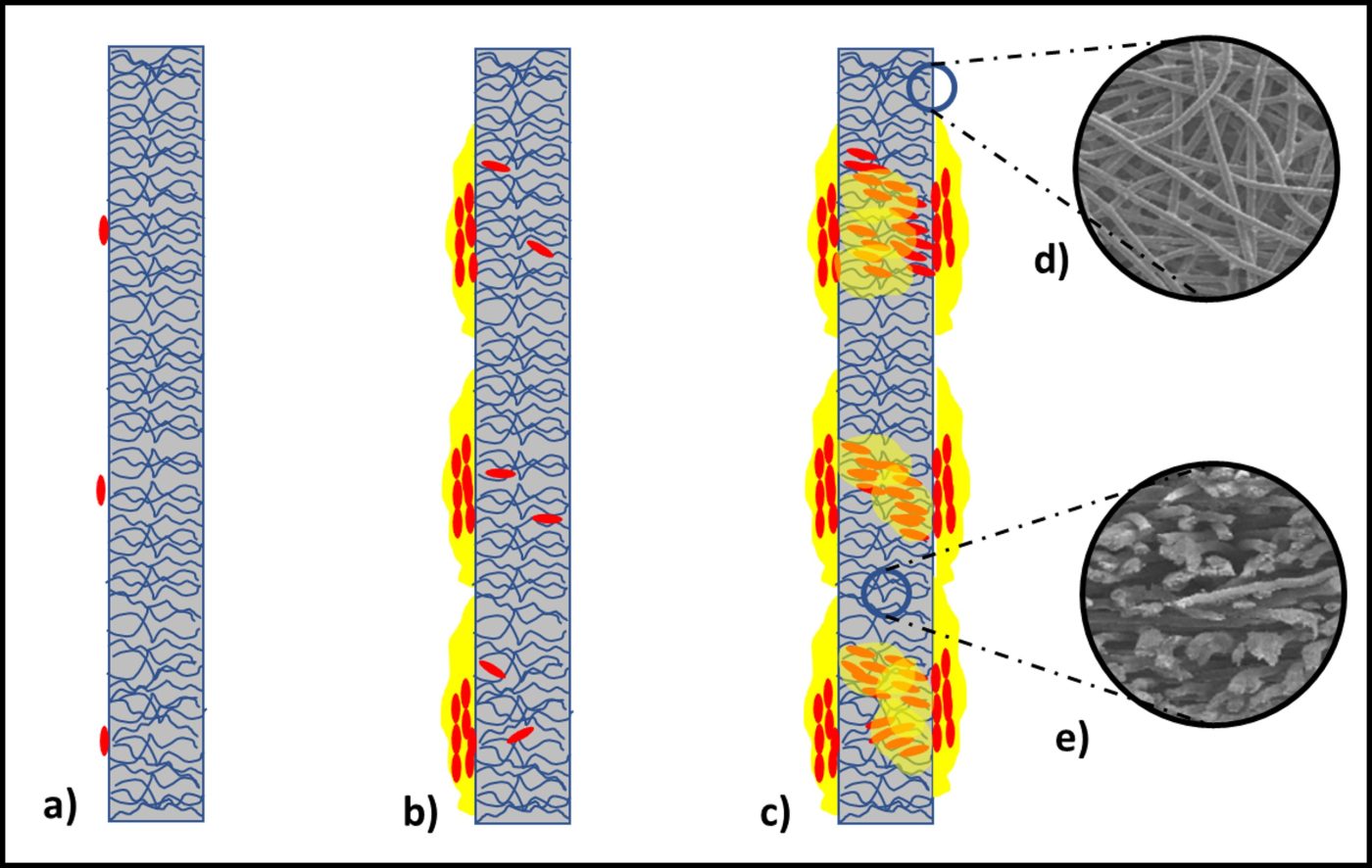

In Figure 5, the oil is flowing from left to right. Unlike organic and inorganic particles, when microbes are trapped onto filter surfaces (Figure 5a) they can reproduce (proliferate) and excrete extracellular polymeric substance (EPS – a blend of various macromolecules that includes lipids, carbohydrates, proteins, nucleic acids, and others). Consequently, filter media are coated with both an increasing mass of cells and EPS (Figure 5b). Microbes trapped within the filter’s matrix can also proliferate and produce EPS. The combination effect is premature filter plugging as indicated by an increased pressure differential across the filter (Figure 5c). Figures 5d and 5e are photomicrographs of a filter’s surface and cross-section – illustrating how the weaved fibers achieve the medium’s designated porosity and filtration efficiency.

Fig 5. Microbes causing premature filter plugging- a) microbes (bacteria) trapped on upstream side of filter; b) trapped microbes proliferate and produce EPS; c) microbial colonization and EPS production no and within matrix restricts oil flow – causing high pressure differential across filter; d) inset showing surface view of filter’s fibers; e) inset showing cross-section view of filter’s fibers.

Corrosion

Microbiologically influenced corrosion (MIC) is an umbrella term that includes direct and indirect mechanisms by which microbes contribute to corrosion. I’ll devote a future What’s New article to explaining MIC. For now, I’ll simply note that MIC most commonly contributes to failures of pressurized lines and that (have you read this before?) MIC shares symptoms with abiotic corrosion mechanisms.

Reservoir fouling

Figures 3 and 4 illustrate mild forms of invert emulsion. Figure 6 is a sample from the bottom of a turbine oil reservoir. The invert emulsion residue that was produced by microbes in the system was nearly solid. To remove it from the reservoir, operators had to drain the tank, shovel out the semi-sold mass from the bottom 5 cm (2 in), then use high pressure, hot water and detergent to clean the reservoir before retuning it to service. Lines in which this mass had congealed had to be replaced.

Fig 6. Turbine oil reservoir bottom sample showing 5 cm layer of semi-solid, invert emulsion associated with uncontrolled microbial contamination.

Summary

When sufficient water to present, microbes can proliferate and be metabolically active in turbine oil systems. When this happens, microbial populations can degrade both the oil and the system. For a full treatment of the problem and its mitigation, read Energy Institute’s Guidelines on detecting, controlling, and mitigating microbial growth in oils and fuels used at power generation facilities, 1 st Ed., June 2020, ISBN 978 1 78725 188 5 (Figure 7).

Fig 7. Cover – EI Guidelines on detecting, controlling, and mitigating microbial growth in oils and fuels used at power generation facilities, 2020.

As always, I look forward to receiving your questions and comments at fredp@biodeterioration-control.com.