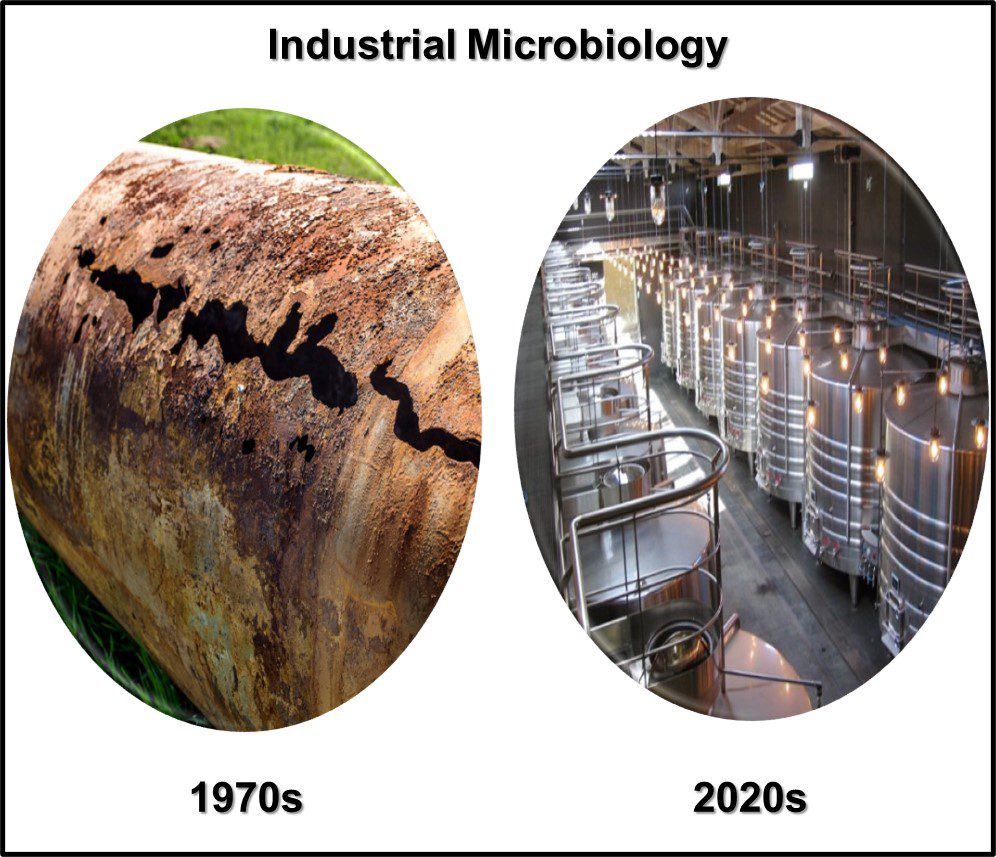

Left Image – microbiologically influenced corrosion of petroleum pipeline; Right Image – industrial scale fermentation.

Introduction

In a recent book chapter (Noha M. Sorour, et al. 2017. Chapter 3 – Microbial Biosynthesis of Health-Promoting Food Ingredients, In: Alexandru Mihai Grumezescu, Alina Maria Holban, Eds, In Handbook of Food Bioengineering, Food Biosynthesis, pp: 25-54, Academic Press, New York, ISBN 9780128113721, https://www.sciencedirect.com/science/article/abs/pii/B9780128113721000038) industrial microbiology was defined as a branch of applied microbiology in which microorganisms are used for the production of important substances, such as antibiotics, food products, enzymes, amino acids, vaccines, and fine chemicals. With respect to the scope, objectives, and activities, industrial microbiology is synonymous with the term fermentation, as fermentation includes any process mediated by or involving microorganisms in which a product of economic value is obtained. There was no mention of microbial contamination control in this definition. I feel as though I missed The Memo.

When I first joined the organization then known as the Society of Industrial Microbiology (SIM; now, Society of Industrial Microbiology and Biotechnology – SIMB), annual meeting sessions largely focused on sessions about different ways that microbes could cause damage to industrial systems. In recent years, sessions on microbial contamination control have largely disappeared from annual meeting programs. What is going on?

Fermentation Art and Science

I don’t mean to suggest that historically, industrial microbiology did not include fermentation. In fact, archeological evidence suggests that the art of fermentation dates nearly as far back as ancient agriculture (i.e., before 10,000 BCE – Figure 1a). Leavened bread and fermented beverages have existed at least as long as written records. During the mid-19th century, Louis Pasteur and Robert Koch, respectively, proved conclusively that microorganisms were responsible for food spoilage and disease. In particular, Pasture championed the marriage of art and science in the world of fermentation (Figure 1b). Since the mid-20th century fermentation process science has expanded to include bioconversion of diverse feed stocks into innumerable products including, but not limited to, foods, flavors, pharmaceuticals, polymers, and solvents (Figure 1c). Fermentation science is now under the moniker biotechnology (the American Chemical Society defines biotechnology as “the application of biological organisms, systems, or processes by various industries to learning about the science of life and the improvement of the value of materials and organisms, such as pharmaceuticals, crops, and livestock.”).

Fig 1. History of fermentation – a) ancient grain collecting and fermentation; b) mid-19th century brewery; c) modern biotechnology facility.

We have come a long way from the earliest attempts to ferment foods as a means of preservation and alcoholic beverage production! Still, I feel that industrial microbiology’s current definition ignores an important aspect of the discipline’s scope – microbiological contamination control.

Microbiological Contamination Control

Biocides ascendant

It has been speculated that the earliest attempts to preserve foods was through fermentation and that kimchi (fermented cabbage) was developed in the 10th century BCE. The earliest recorded use of minerals as biocidal agents was the use of sulfur in ~2,500 BCE. Arsenic, lead, mercury, have been used as antimicrobial control agents since at least the 2nd century BCE. In 1867, Joseph Lister introduced the first organic antimicrobial agent – phenol (Figure 2a) – as an antimicrobial agent to prevent wound sepsis. Subsequently, phenol was used widely as a surface contact disinfectant.

The number of available organic microbicides grew dramatically between the 1930s and 1970s. Early oilfield microbiology research demonstrated that polychlorinated phenols (trichlorophenol and pentachlorophenol) did an excellent job of inhibiting sulfate reducing bacteria from causing problems when water was injected into petroleum formations. From the mid-1940s until their use was banned in the early 1970s, polychlorinated phenols (Figures 2b and 2c) were the predominant oilfield microbicides. Once chlorinated phenols were banned, glutaraldehyde (Figure 2d) and quaternary ammonium compounds (Quats – Figure 2e) became the most used oilfield microbicides. There are now hundreds of quats available for use in various applications. After the development of water-miscible metalworking fluids (MWF), the need for microbicides became apparent. Hexahydro-1,3,5-tris(2-hydroxyethyl)-s-triazine (Figure 2f) and several oxazolidine biocides dominated the application, although, by 1990, nearly 200 active substances for use n MWF were approved by the U.S. EPA. I’m not trying to provide a comprehensive review of organic biocide history here. My point is that, entering into the 1990s, there were many of microbicidal active substances available for use in industrial applications.

Fig 2. Selected organic microbicides – a) phenol; b) trichlorophenol; c) pentachlorophenol; d) glutaraldehyde; e) quaternary ammonium compound (R1 through R4 are organic – CH – radicals, the chemistry of which can vary by chain length, degree of substitution, presence of oxygen, and ring structures); f) Hexahydro-1,3,5-tris(2-hydroxyethyl)-s-triazine.

Biocides descendant

Since the mid-1990s, two factors have contributed to substantially reduce the number of active substances available to use in various industries – regulatory pressure and industry consolidation (Figure 3).

Fig 3. The incredible shrinking list of microbicidal active substances and the factors driving that shrinkage.

First the agencies responsible for biocide regulation have changed. In the U.S., the U.S. Environmental Protection Agency assumed responsibility in the early 1970s. In the EU, the European Chemical Agency’s Biocidal Products Committee was chartered under the 1998 Biocidal Products Directive (Directive 98/8/EC). As I’ve noted above, tri- and pentachlorophenol use was banned in the early 1970s after they were found to be carcinogenic and persistent in the environment. The types of toxicity and environmental fate data needed to support biocidal product registrations, are substantially greater than those needed to register non-biocidal, technical products. The cost of completing a full toxicological evaluation are estimated at $2 U.S. million to >$10 million U.S. For biocides used in niche applications, such as MWF or jet fuel, the addressable market does not justify the expense. Moreover, the timeline between initial registration application and regulatory agency approval can be greater than ten years. In the U.S., after recommending that formaldehyde be found to pose an unreasonable risk, the EPA has targeted formaldehyde-condensate microbicides for special scrutiny. This, despite the fact that the toxicological profiles of formaldehyde-condensate microbicides is substantially different (more benign) than that of formaldehyde and the free-formaldehyde cannot be detected in fluids treated with these active substances.

The second factor is industry consolidation. In 1990, there were numerous microbicide producers in the U.S. and EU. Since then, corporate acquisition has eliminated >90 % of the companies that once produced microbicides. In most cases, the industrial biocide business units represent a negligible fraction of the companies’ annual revenues. In corporations where projects valued at <$100 million U.S. are not supported, new biocidal product development never stands a chance (the total MWF biocide market is estimated at <$300 million U.S.).

Combined, these two factors translate to a greatly reduced list of active substances approved for use in various industrial applications and, in most market sectors, reduced career opportunities for microbiologists.

Old-school industrial microbiology did not focus solely on biocide selection and use. However, controlling microbiological contamination and reducing biodeterioration risk was a primary research objective. Thus the increased regulator pressure against biocide use has also adversely affected this branch of microbial ecology research.

Impact on Old-School Industrial Microbiologists

When I’m asked about my profession, I tell folks that I am an industrial microbial ecologist. I investigate the ecology of microorganisms that infect industrial systems and potentially cause damage to the systems, their contents, or both. There are industrial sectors in which microbial contamination control is still recognized as being a valuable pursuit. For example, there’s a considerable amount of excellent oilfield microbiology research and development. Two international conferences focus on the topic (ISMOS and RMF). Similarly, the Energy Institute has an active Petroleum Microbiology Committee, ASTM has a Fuel Microbiology Working Group, and the International Air Transport Association has a Jet Fuel Microbiology Panel. Conversely, at the STLE 2024 Annual Meeting, I presented the only paper addressing MWF microbiology. Historically, STLE Annual Meeting programs included five to ten papers, presented by representatives of biocide producers, MWF compounders, and MWF end users. Those companies who still have staff microbiologists are not allowing those people to participate in professional society activities. This lack of support in the MWF sector is particularly notable because the tools now available for understanding the microbial ecology of MWF systems promise to provide ways to develop more cost-effective microbial contamination control strategies. Moreover, the potential adverse health effects of uncontrolled microbial contamination have been well documented.

Since 1999, I’ve been teaching MWF microbiology as part of STLE’s education program. I’ve carried on a legacy started by Prof. Ed Bennett (University of Houston) – the individual I consider to be the father of MWF microbiology and the person responsible for initiating educational programs at STLE (then ASLE) annual meetings. Ed was succeeded by another MWF microbiologist (Frank Mallek) and Frank was succeeded by Prof Harold Rossmoore (Wayne State University). After 25 years as an STLE course developer, I’m stepping down. Although I have a successor in mind, I don’t know whether his employer will support his involvement with STLE education. I anticipate that there will be interesting times ahead and that a new generation of industrial microbial ecologists will need to relearn the lessons learned by previous generations.

As always, please share your comments and questions with me at fredp@biodeterioration-control.com.