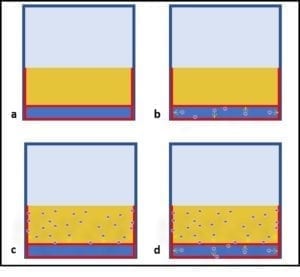

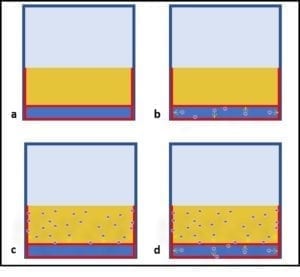

Fig 1. Microbes in fuel systems and the biocides used to control them – a) fuel (yellow-orange) over bottoms-water (dark blue), with red lines showing where microbes tend to accumulate; b) after treatment with water-soluble biocide (purple stars); c) after treatment with fuel-soluble biocide; d) after treatment with universally-soluble biocide.

Where are the bugs? If you intend to use a biocide to disinfect a fuel system, the first question to ask is: “Where are the bugs?” Figure 1a shows where microbes tend to be most abundant in fuel systems. The red lines symbolize microbe accumulations in the bottoms sludge and sediment, at the fuel-water interface, and on tank walls.

Fuel treatment microbicides Microbicides are chemicals that are manufactured and sold for the purpose of killing microbes. They are part of a greater family of chemicals called pesticides or biocides. Formally, microbicides are called antimicrobial pesticides – i.e., they are pesticides that target microbes. I’ll come back to the issue of pesticide registration at the end of the post. For now, I want to split the biocides used for fuel and fuel system treatment into three groups:

- 1. Water-soluble

- 2. Fuel-soluble

- 3. Universally-soluble

Why should I care whether my biocide is water, fuel or universally soluble? Water-soluble biocides Water soluble biocides fall through the product and dissolve into the water-phase (figure 1b). They are not present in the fuel for a long enough period (see

Fuel and Fuel System Microbiology Part 22) to kill microbes either in the fuel-phase or on tank walls exposed to fuel. They can effectively kill microbes in bottoms-water, sludge and sediment, but it is reasonable to ask whether this makes good sense. Typically, when water, sludge, and sediment are vacuumed or drained out of tanks, the wastes are shipped to a biological wastewater treatment plant. Biological wastewater treatment depends on microbes to eat organic molecules to reduce the water’s biochemical oxygen demand (percentage of organic matter that microbes can digest in a five-day period), chemical oxygen demand (percentage of organic matter that is chemically oxidizable – convertible to carbon dioxide), and total petroleum hydrocarbons (TPH). I have never understood the logic for killing microbes that can help the waste treatment process, just before shipping those microbes to waste treatment. Therefore, I have never understood the logic of treating fuels or fuel systems with water soluble biocides.

Fuel-soluble biocides Fuel-soluble biocides (figure 1c) mirror the performance of their water-soluble cousins. These products effectively kill microbes in the fuel and can be somewhat effective against microbes growing on tank walls in contact with the fuel. They can also attack microbes living at the fuel-water interface. They do not contact microbes living either on tank bottoms or on those portions of the tank wall that are in contact with water rather than fuel.

Universally-soluble biocides As their name implies, universally-soluble biocides (figure 1d) can disperse within both the fuel and water phases. Typically, they are fully soluble in fuel and partially soluble in water. Most importantly, they are chemically stable in both phases. As figure 1d illustrates, they can interact with microbes in fuel, in water, at the fuel-water interface, and on all tank surfaces in contact with fuel or water. Consequently, universally-soluble biocides are the most reliable products for disinfecting fuels and fuel systems.

Regulations Pesticides are regulated by the U.S. EPA in the USA. Under the U.S. Federal Insecticide, Fungicide and Rodenticide Act (FIFRA – 7 U.S.C. §136 et seq. [1996]), EPA’s Office of Pesticide Programs had direct responsibility for pesticide registration and management. The details of biocide regulations are found in 40 CFR Chapter I, Subchapter E, Parts 152-180. Outside the U.S., the European Union and many individual countries have regulatory agencies responsible for pesticide approval and oversight. The key point here is that microbicides are highly regulated products. Only registered products may be used. Each registered product has one or more approved end-uses (sites). Two US EPA end-uses sites of interest to us are:

- • For use in treating fuel-associated water, and

- • For use in fuels.

The language can vary among product labels, but the difference between these two general sites is important. The first site applies to water-soluble biocides. The second one refers to fuel-soluble and universally-soluble biocides. If you are considering a microbicide, read the label carefully and make certain that the product has a use in fuels end-use site. There is another fuel-related regulation: 49 CFR Chapter I, Subchapter C, Part 79 Registration of Fuel and Fuel Additives. The regulations under 49 CFR 79 address the use of fuels and fuel additives. Fuels are comprised of molecules built from carbon (C), hydrogen (H), oxygen (O), nitrogen (N), and sulfur (S). This list of elements has the acronym, CHONS. Fuel additives that contain only CHONS are designated as being substantially similar to fuel (subsim). The American Petroleum Institute (API) has created a consortium of companies who produce subsim products. Once a suitable test method has been developed, the members of the consortium will share the cost of engine emission toxicological tests. Each member’s share will be based on the volume of CHONS product they produce. Recognizing the infinitesimally small volume of fuel treatment microbicides, relative to fuels, API charges microbicide manufacturers a minimal fee for consortium membership. The bottom-line here is that fuel treatment microbicides should have two registrations:

- 1. A pesticide registration, and

- 2. A fuel additive registration.

None of the water-treatment microbicides that list a variation on the theme of “for use in treating fuel-associated water” are also registered as fuel additives. Most of the products that list “fuel treatment” as an end-use site, carry both registrations. Just to help confuse users, there are several products that have waivers from the U.S. EPA’s Fuel Programs Manager. These waivers are based on the assumption that the microbicides are used to treat fuel systems rather than fuels, and that none of the product remains dispersed or dissolved in fuel. In part 22, I’ll write about how to use universally-soluble fuel treatment microbicides. In the meantime, if you have questions or comments about today’s post, please contact me at

fredp@biodeterioration-control.com.

Disclaimer As in my previous two post, I’ll open with a disclaimer. Microbes are ubiquitous. There are extraordinarily few habitats on earth where thriving, microbial communities have not been detected. In practical terms, this means that it is unlikely that operators will ever have a completely sterile fuel system or that they will reduce their fuel system biodeterioration risk to zero. Biodeterioration can still occur in the best maintained fuel systems. However, the risk of it occurring in an inadequately maintained system is much more likely.